a new paradigm of performance in Endodontics

Confidence

Paradigm files are more resistant to separation from torsional overload than the market leading heat-treated multi-taper file.

Efficiency

Paradigm files have a harder cutting edge to stay sharper longer for cutting efficiency and superior cleaning.

Flexibility

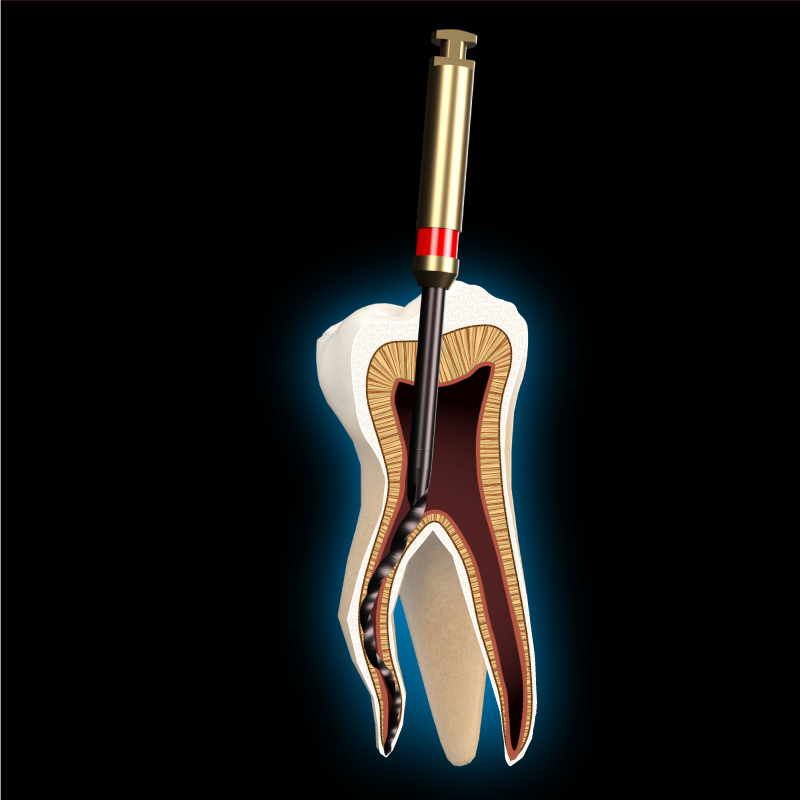

Paradigm files are 20% more flexible than the market leading heat-treated multi-taper file for improved performance in difficult canals.

Endurance

Paradigm files are laser processed to a hybrid microstructure for torsional resistance without giving up durability in cyclic bend fatigue life.

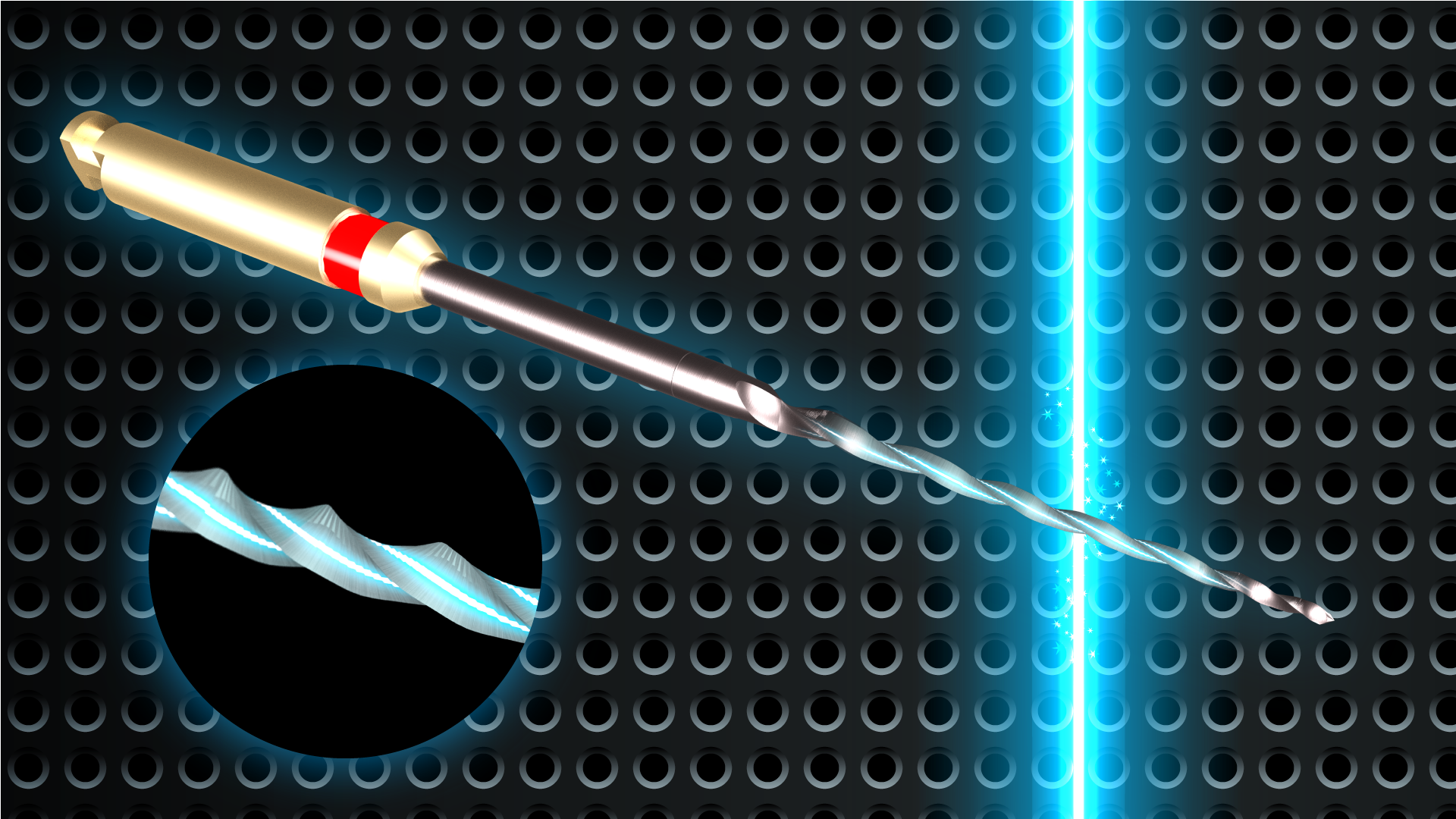

The NEW Paradigm endofiles with LaserFlex technology

Features

- Patented LaserFlex process

- Hybrid BX microstructure

- Flexible core with harder cutting edge

- Focused flexibility across the section and along the length

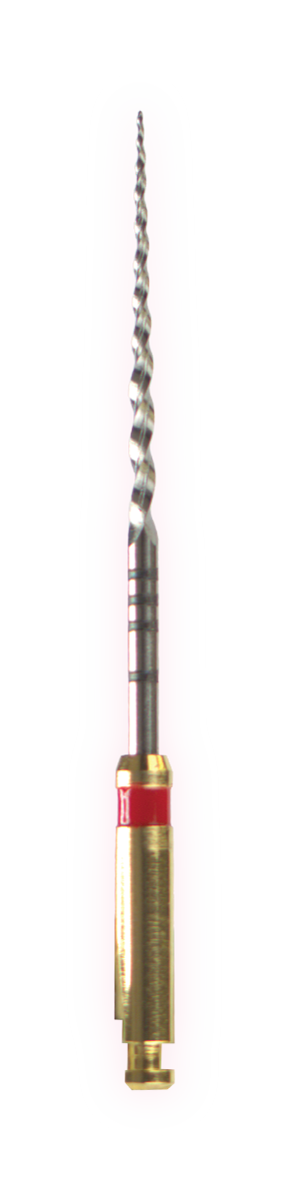

- Multiple taper design

- Non cutting tip

- Compatible with standard handpieces

- Standard workflow

Find your perfect balance with LaserFlex Technology

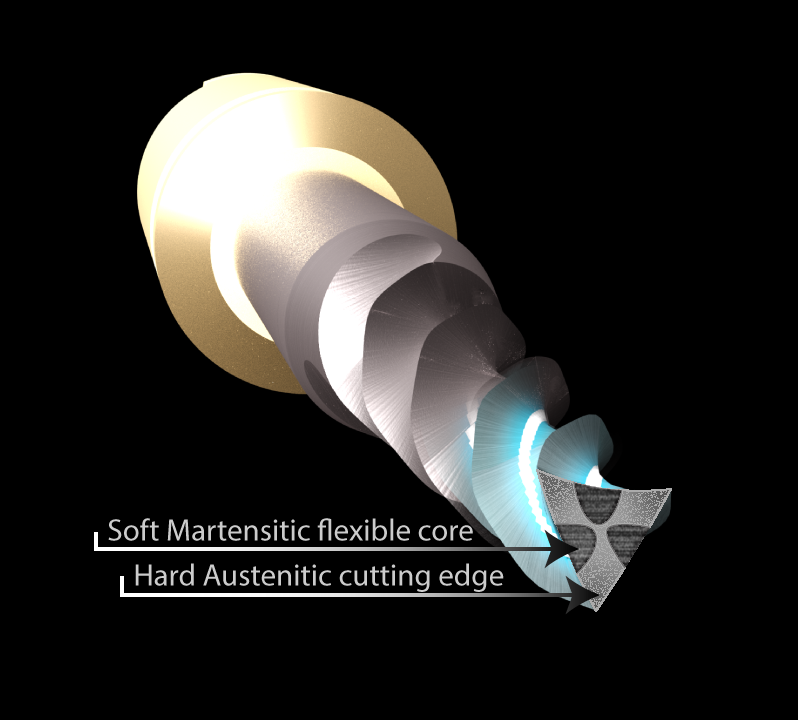

Paradigm endodontic files are treated with LaserFlex technology. We use a patented laser process to selectively program the NiTi files with austenite (B2) and martensite (B19) phases across the section of the file.

The resulting hybrid mixture of microstructures in the BX-series files provides a balance of flexibility, torsional strength, durability and cutting edge retention.

The LaserFlex technology that produces the BX-series microstructure eliminates the tradeoffs found in regular heat-treated NiTi files, such as poor torsional strength, unwinding and rapid edge wear or deformation. These issues may result in poor canal cleaning, binding and file separation.

Paradigm BX-series files provide exceptional confidence for instrumenting the most difficult canals. The hybrid microstructure provides higher torsional resilience and resistance to separation, a harder cutting edge to stay sharp longer for improved cleaning, and 20% more flexibility for navigating tortuous paths.

Paradigm is engineered for flexibility. Flexible files are able to navigate tough glide paths. Some heat-treated files provide flexibility by tempering the microstructure of the Nitinol base material, but this flexibility gives up strength and hardness. With Paradigm we targeted the tradeoffs in heat-treated files that are sacrificed for improved flexibility.

Nitinol is heat-treated to convert an austenitic microstructure to martensite. Martensite demonstrates the shape memory effect and is malleable at lower temperatures. The mechanical properties achieved with a heat-treated microstructure increase flexibility; however, the corollary is lower resilience and lower hardness. Trade-offs that can result in a file that twists (or unwinds) in the canal and looses a sharp cutting edge due to wear.

Using the patented LaserFlex technology, we have engineered a process whereby a martensitic microstructure can be programmed into a discrete area in the cross-section of the file. Specifically, we use a laser to vaporize Nickel from the Nitinol material, replacing the effects of heat-treatment. Using this process, we can create a hybrid microstructure with precision control over the mechanical properties along the length, and across the width, of the file.

Technical Data

BX (rotary)

Cross section shape: Triangular

Material: Nickel-Titanium

Sizes available:

| Part No. | Length | Tip Dia. | Taper |

| AX | 19 mm | 018 | Multi-taper |

| A1 | 25 mm | 017 | Multi-taper |

| A2 | 25 mm | 018 | Multi-taper |

| M1 | 25 mm | 020 | Multi-taper |

| M2 | 25 mm | 025 | Multi-taper |

| M3 | 25 mm | 030 | Multi-taper |

| M4 | 25 mm | 040 | Multi-taper |

| M5 | 25 mm | 045 | Multi-taper |

Quantum (reciprocating)

Cross section shape: Parallelogram

Material: Nickel-Titanium

Sizes available:

| Part No. | Length | Tip Dia. | Taper |

| SM | 25 mm | 020 | 0.07 v |

| PR | 25 mm | 025 | 0.07 v |

| MD | 25 mm | 035 | 0.06 v |

| LG | 25 mm | 045 | 0.05 v |

Get started with Paradigm

Now available in the US and Canada

Call 519-880-0100 to order or shop online

Paradigm endodontic files are made in Canada by Smarter Alloys Inc

Phone

(519) 880-0100

info@smarteralloys.com

Office

221 Shearson Cres.

Cambridge, ON N1T 1J5

Canada